Product Description:

Our Graphite Raw Material is a premium grade product specifically designed to meet the rigorous demands of various industrial applications. Sourced from high-quality Natural Graphitic Minerals, this raw graphite material offers exceptional purity and consistency, making it an ideal choice for manufacturers and researchers alike. With an emphasis on quality and performance, this graphite product stands out as a reliable Raw Graphitic Feed Material suitable for a wide range of uses.

The Model No for this product is listed as Standard, ensuring that it adheres to well-established specifications that meet industry benchmarks. This standardization guarantees uniformity in every batch supplied, providing customers with a dependable source of graphite that can be seamlessly integrated into their production processes without concerns about variability.

One of the key attributes of this Graphite Raw Material is its exceptional purity level of 99.9%. Such a high degree of purity is critical, especially in applications where impurities can adversely affect the final product’s quality or performance. This purity is achieved through meticulous processing and quality control measures, ensuring that the Natural Carbonaceous Feed used is free from contaminants and unwanted materials.

The carbon content of the product is an impressive 95%, highlighting its excellent carbonaceous nature. This high carbon content is a testament to the natural origin of the graphite, derived from carefully selected Natural Graphitic Minerals. The substantial carbon content ensures optimal conductivity, thermal stability, and chemical inertness, which are essential properties for applications in batteries, lubricants, refractories, and other industrial sectors.

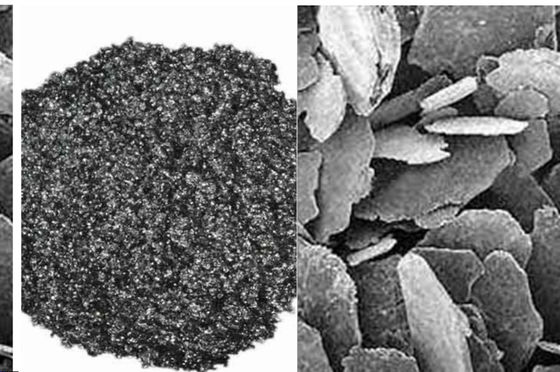

In terms of physical characteristics, the Bulk Density of this graphite raw material is 0.6 grams per cubic centimeter (G/cm³). This density measurement reflects the material’s compactness and is an important factor for storage, transportation, and processing considerations. The bulk density also influences the behavior of the graphite when used as a feedstock in various manufacturing processes, impacting factors like packing, flowability, and mixing efficiency.

We understand the importance of validating the quality of raw materials before committing to large-scale purchases. Therefore, we provide samples of our Graphite Raw Material upon request. This allows customers to conduct their own testing and evaluation, ensuring that the Raw Graphitic Feed Material meets their specific requirements and standards before procurement. Our commitment to transparency and customer satisfaction is reflected in this practice, helping clients make informed decisions.

The versatility of this graphite raw material is further enhanced by its natural origin. Being derived from Natural Graphitic Minerals, it maintains the inherent benefits of natural carbonaceous feedstocks, such as environmental friendliness and sustainability. This makes it an attractive option for industries aiming to incorporate more natural and eco-conscious materials into their production lines.

In summary, our Graphite Raw Material offers a combination of high purity (99.9%), substantial carbon content (95%), and a practical bulk density (0.6 G/cm³), all sourced from authentic Natural Graphitic Minerals. With a Standard Model No and the provision of samples for quality assurance, this product is a dependable Raw Graphitic Feed Material that caters to diverse industrial needs. Whether for use in advanced composites, refractory materials, battery technologies, or other specialized applications, this graphite material provides the performance and reliability that industries demand.

Features:

-

Product Name: Graphite Raw Material

-

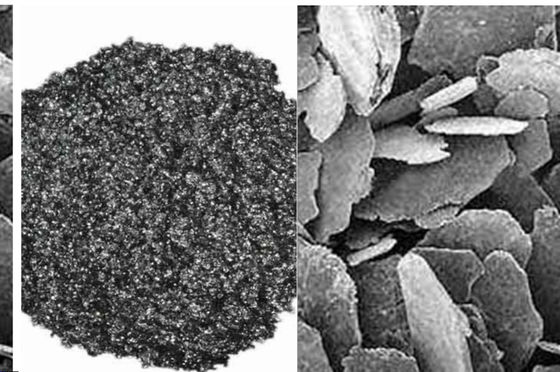

Colour: Black Powder

-

Bulk Density: 0.6 G/cm³

-

Model No: Standard

-

Purity: 99.9%

-

Sample: Provide

-

Made from high-quality Carbon-Based Feed Materials

-

Derived from Natural Graphitic Minerals ensuring superior quality

-

Contains High-Purity Carbon Feed suitable for various industrial applications

Technical Parameters:

|

Model No

|

Standard

|

|

Colour

|

Black Powder

|

|

Sample

|

Provide

|

|

Bulk Density

|

0.6 G/cm³

|

|

Carbon Content

|

95%

|

|

Purity

|

99.9%

|

Applications:

The Graphite Raw Material, characterized by a purity of 99.9% and a carbon content of 95%, is an essential carbonaceous raw mineral widely used in various industrial applications. With its standard model specification and a bulk density of 0.6 g/cm³, this raw graphitic feed material offers excellent quality and consistency, making it an ideal choice for numerous manufacturing and processing scenarios.

One of the primary application occasions for this carbon-based feed material is in the production of refractory materials. Due to its high purity and carbon content, the graphite raw material serves as a crucial component in manufacturing heat-resistant bricks and linings used in furnaces, kilns, and reactors. These refractories benefit from the material’s excellent thermal conductivity and resistance to chemical corrosion, ensuring durability and efficiency in high-temperature environments.

Additionally, this raw graphitic feed material finds extensive use in the electrode industry. Its high carbon content makes it suitable for producing electrodes used in electric arc furnaces, batteries, and other electrochemical applications. The material’s consistent quality and bulk density of 0.6 g/cm³ contribute to stable electrical conductivity and mechanical strength, enhancing the performance of carbon electrodes.

In the field of lubrication, the graphite raw material is applied as a solid lubricant additive. Its layered structure and purity make it effective in reducing friction and wear in machinery and mechanical systems, particularly in harsh operating conditions. This application scenario highlights the versatility of carbonaceous raw minerals in improving equipment longevity and operational efficiency.

The graphite raw material is also utilized in the production of carbon brushes, crucibles, and carbon composites. Its high purity and carbon content ensure superior performance in electrical contacts, melting processes, and composite materials manufacturing. These applications demonstrate the product’s adaptability across a range of industrial sectors.

For quality assurance and development purposes, samples of this carbon-based feed material are readily provided. This allows potential users to evaluate its properties and suitability for specific applications before committing to bulk purchases. The availability of samples underscores the manufacturer’s confidence in the product’s performance and its alignment with industry standards.

In summary, the Graphite Raw Material with 99.9% purity, 95% carbon content, and a bulk density of 0.6 g/cm³ serves as a fundamental carbonaceous raw mineral. Its applications span refractory production, electrode manufacturing, lubrication, and composite materials, making it an indispensable raw graphitic feed material for various industrial scenarios.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!

Overall Rating

Rating Snapshot

The following is the distribution of all ratingsAll Reviews